Making the ROI Business Decision about Revit Add-ins

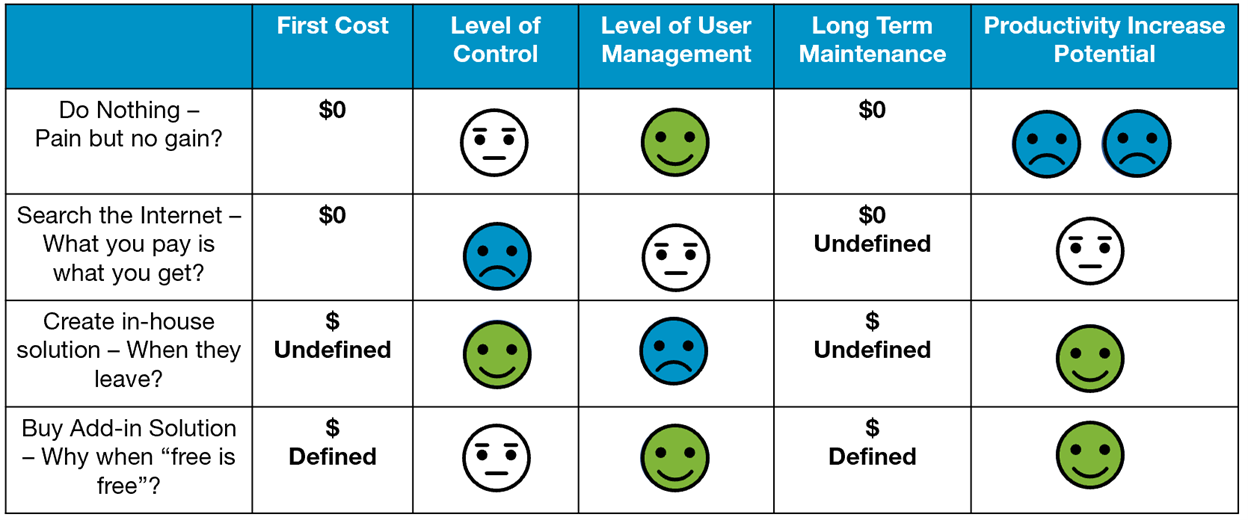

Every AEC firm has a project situation where this thought occurs: “We want to streamline this process. Our software can design and/or document the project, but we need more.” The options for the owner or firm are:

- Do nothing. Live with the pain

- Search to see if there is something free on the Internet

- Create an in-house application (software development)

- Subscribe to an add-in program (from a third-party provider)

Before exploring these options, from the one with the lowest initial cost to the one with the highest, let’s define return on investment (ROI). According to Investopedia, ROI is “a performance measure used to evaluate the efficiency of an investment or compare the efficiency of a number of different investments. ROI tries to directly measure the amount of return on a particular investment, relative to the investment’s cost.”

Because AEC firms are service-based companies, to determine ROI, they must look at a combination of first costs (purchase investment), on-going costs (maintenance), and cost savings (quicker completion of tasks/work) as part of the business decision. For the purpose of this article:

(First Cost) + (Ongoing Costs) – (Productivity Savings) = Total Cost

This simplified calculation says there are first costs and ongoing costs that must be serviced by the productivity gains. Without productivity gains, all that remains are costs.

Another factor AEC decision makers must determine is if the process/product they are considering is the right tool for the project/process. For example, every person working around the house finds out that you can use a screwdriver or a hammer to countersink a screw. In fact, many ‘newbie’ homeowners have tried hammering a screw into a piece of knotty wood. They find, though it is possible, the result is neither efficient nor does it create an elegant finished product. The point is that decision makers looking to streamline processes must find the right tool for the job. The jobs will be different, therefore, the tools needed have to be different. One reason contractors buy power equipment is that it helps them be quicker at their jobs than hand equipment. The advent of air-powered nailers (more expensive than hammers) increased productivity, provided consistent results, and reduced errors, and they are now the industry standard in wood construction.

In this article, I review a decision-making process that will increase a firm’s success in streamlining the project workflow.

Addressing the Pain: A Look at the Four Options

Do Nothing

This approach, sometimes called ‘other use of capital’ simply states, “if it ain’t broke don’t fix it,” or “we have always done it this way,” or “the authoring program should do this.” All of the above thoughts have some validity but are short-sighted. The ‘Do Nothing’ approach ignores the high on-going costs of inefficiency and the possibility of errors while having a zero-productivity enhancing element. In fact, doing nothing increases the pain, decreasing employee morale and leading to other productivity losses.

We choose to do nothing because it is the easiest answer. We can sit by and silently complain about the authoring software. However, it is imperative that decision makers and leadership find solutions that solve problems, reduce errors, and increase productivity.

Questions to ask:

- Do we have a problem, a pain?

- Define the pain – What is the existing and the desired workflow? Diagram the desired workflow showing the entire process, including pinch points.

- What are other firms doing to fix the pain?

Search for a Free Solution (The Internet Route)

Often this is the first ‘go to’ strategy after the pain has been felt. We Internet-search the pain and look at the first 3-4 results to find the ‘magic’ aspirin for the pain. Often, the results are as relevant as when searching for the best car for 2020; they are not very specific and do not provide a valid methodology for identifying a successful solution.

When Revit first became an industry standard, the need for Revit families exploded. AEC companies downloaded ‘free’ families only to find out that they were bloated (file size), not created well, or not suitable for the firm’s desired usage. Though the first cost was low and there were zero maintenance costs, the cost savings were negligible, or simply the pain was still there. Sometimes the pain increased because of the use of inappropriate families to the firm.

Today, add-in solutions run the spectrum from good to not-so-good. Careful consideration of the decision-making process is required. You should evaluate free solutions in the same way paid solutions are evaluated:

- Test the solution thoroughly, including BIM model fidelity

- Determine if the free solution solves the whole problem or just a portion of it

- Understand the business model of the solution seller

Create In-house Solutions

The in-house software solution requires hiring or utilizing in-house resources to create a bespoke solution. New graphical software programming interfaces can be used, and those bespoke solutions can have great value. Also, the use of traditional programming solutions (C#, Python, JSON, etc.) has lowered the preliminary learning threshold. However, on-going costs to learn and maintain the program are required.

In-house solutions have a fairly low first cost but a high on-going cost. The hidden cost is the ongoing maintenance of the solution. That hidden cost includes updates when a new version of the authoring software changes the underlying connections between the solution and the authoring software. The biggest issue to address is what to do if the in-house software developer leaves the company. Based on our discussions with people at numerous AEC firms, we have found that this happens often, and when it does, the pain returns and the money expended into the in-house solution become a lost investment (non-ongoing benefit).

Items to consider:

- Assess in-house resources and outside consultants – understand the cost and availability of each option

- Determine a transition strategy to plan what happens when the in-house person is not available

- Understand that bespoke solutions tend to work best for bespoke pains (crafted solution for a process that is unique to a project)

- Model the ongoing costs and time required to maintain bespoke solutions

Subscribe to a Third-party Solution

This option has the highest first cost. As buyers, we always wonder if there is a lower first cost; however, as the formula at the beginning of the article states, first cost is only one-third of the equation. All purchased solutions must be evaluated and measured by the total cost and benefits.

In reviewing third-party solutions, you should evaluate the seller. Some information to obtain is:

- How long has the seller been developing Revit add-ins?

- How long has the seller been around?

- How stable is the software? Can it damage your Revit database?

- What are their support mechanisms? What does the seller do when a user encounters an issue, including providing in-program help features?

- Does the seller listen when you have feature requests, or more importantly do they listen?

- Can the seller produce ROI information and show why their solution will save the user time (money)?

Return on Investment

When AEC firms invest in a solution, the desired result are productivity gains. How can firms determine what productivity gains are available to be harvested? Revit add-ins support the authoring software (Revit), which is based solely upon labor costs, unlike construction pre-fabrication that saves labor and material costs. So how do we calculate labor savings?

Using software is very labor-intensive. Productivity and efficiency improvements considerations are:

(Source: 2019 DBEI Presentation S3.1 – Kelly Cone)

- How much time did the process take to do before?

- How much time does it take to do now?

- How much time is saved?

- How much time will it take when you are done?

- Based on the time savings, how much more work can the users do in a day?

- What is the average labor cost (burdened and unburdened) of the users?

- How many users do you have now?

- How many projects can those people currently produce?

- How many more projects could they produce if they were more efficient?

Some of these considerations are firm specific (average labor cost, number of people in firm, projects per employee, etc.) and can be determined by firm ownership. Labor return on investment is hard to determine.

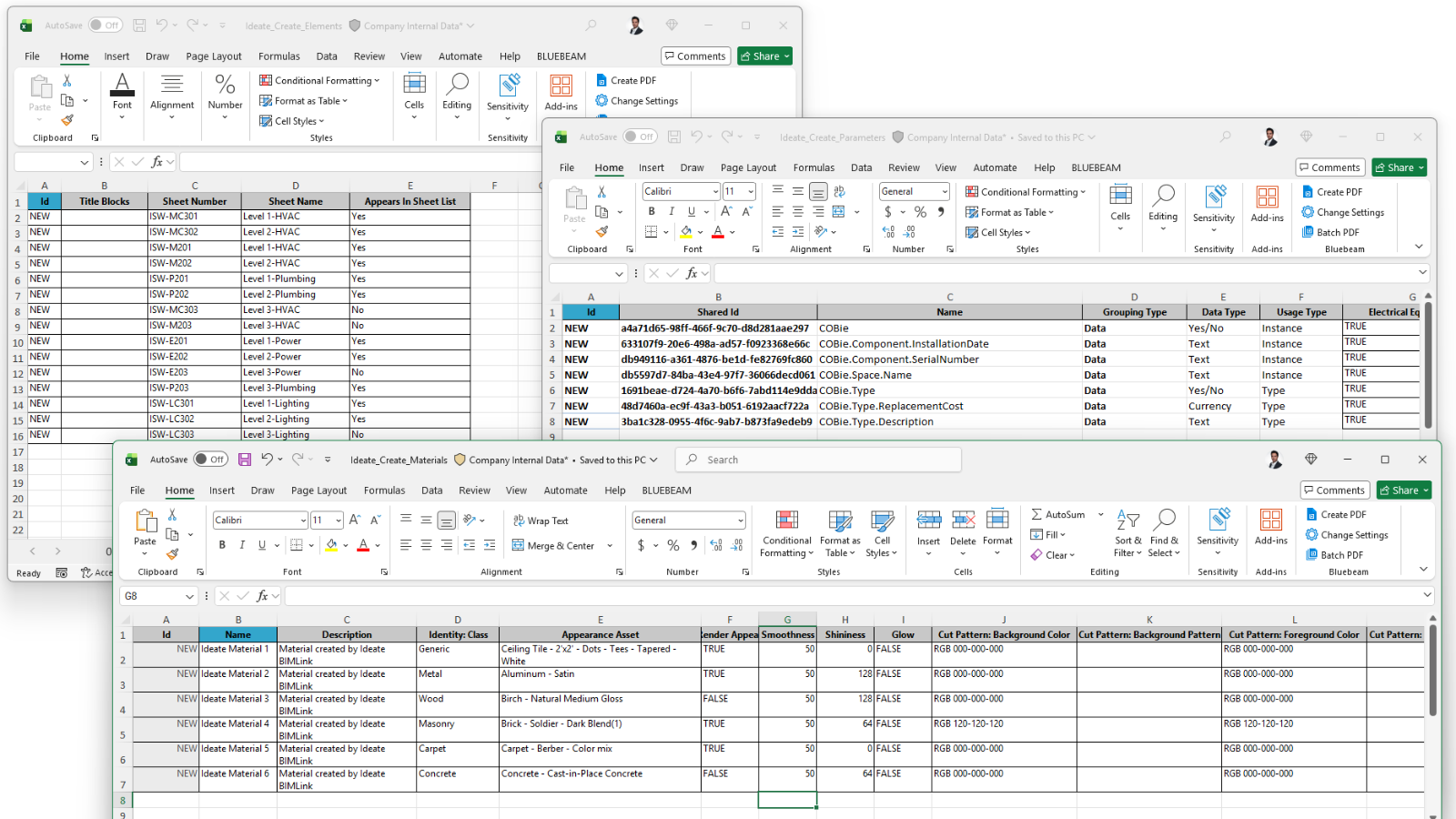

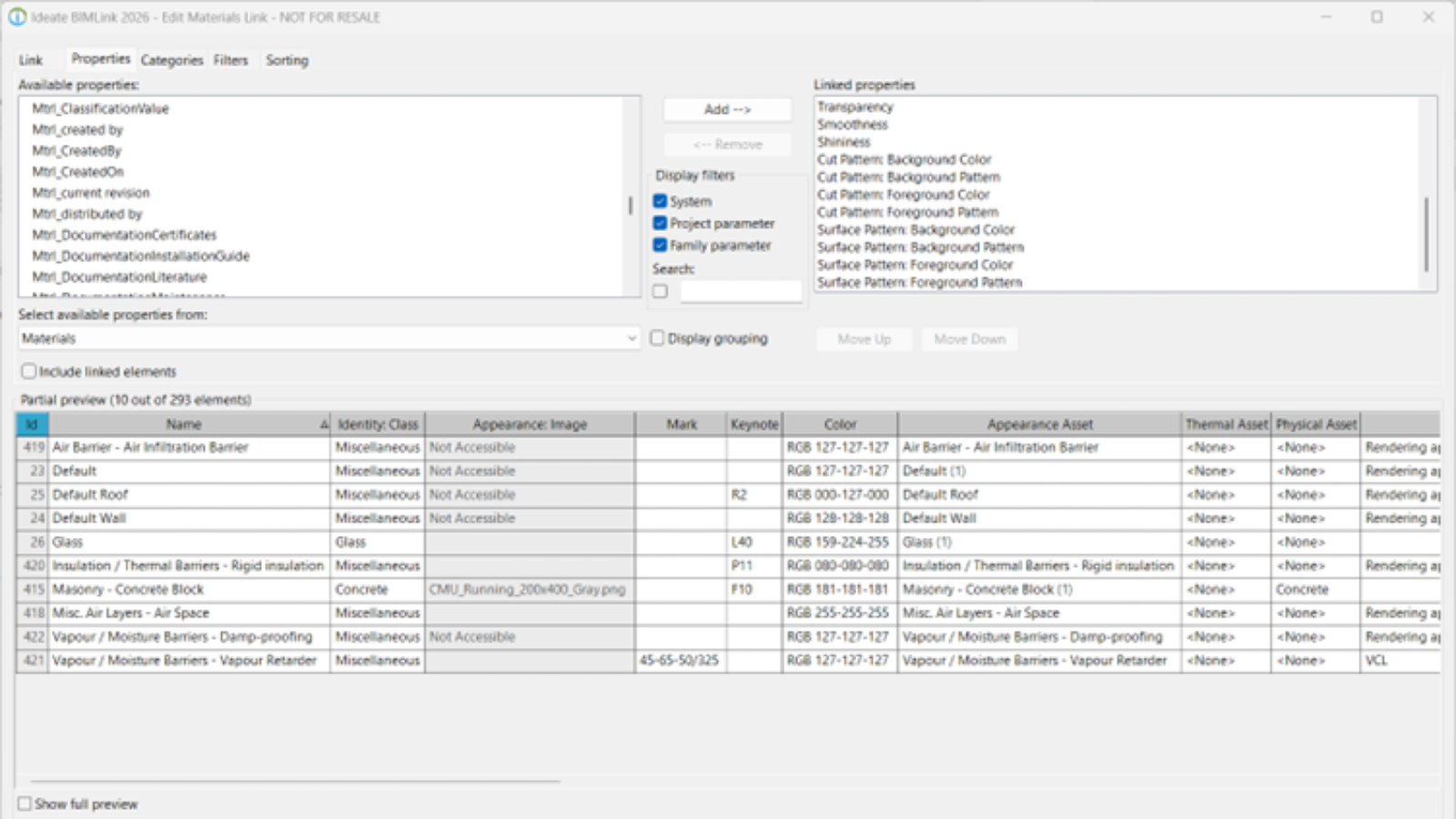

There are not many studies on third-party software ROI, because it can be hard to quantify the metrics of time required to do an existing process vs. time required to do the same process with a new software. Ideate Software reached out to AEC firms to understand the time they saved by using its Revit add-ins. URLs with the results include:

- Ideate BIMLink ROI – an overview

- Ideate Explorer ROI – an overview

- Making the Case for Purchasing Plug-in Software

- Effectively Measuring Return on Investment of IdeateApps and BIM - user analysis of ROI

- Top ROI Workflows for BIM Professionals - showing the top ROI workflow gains

What these results show is that there are productivity gains that can be achieved with the usage of a Revit add-in. Through our studies, we have documented that our add-in programs do provide productivity gains, above any purchase cost, and usually within the first project usage. We have also determined that to achieve those gains, you need:

- Upper management buy-in to create/modify workflows to leverage the software

- To use the Help files within the program (good software has great in software help)

- User training (good software should have good training videos) to assist in the process transition

Conclusion

Though the process may seem daunting, this article articulates a defined process AEC firms can use to determine which method to follow (do nothing through purchasing software) after a new workflow is required, the relative benefits and risks associated with each method, and how return on investment can be analyzed in a labor-intensive service industry. Productivity gains are more important than first costs in the equation. Return on investment should drive the decision.